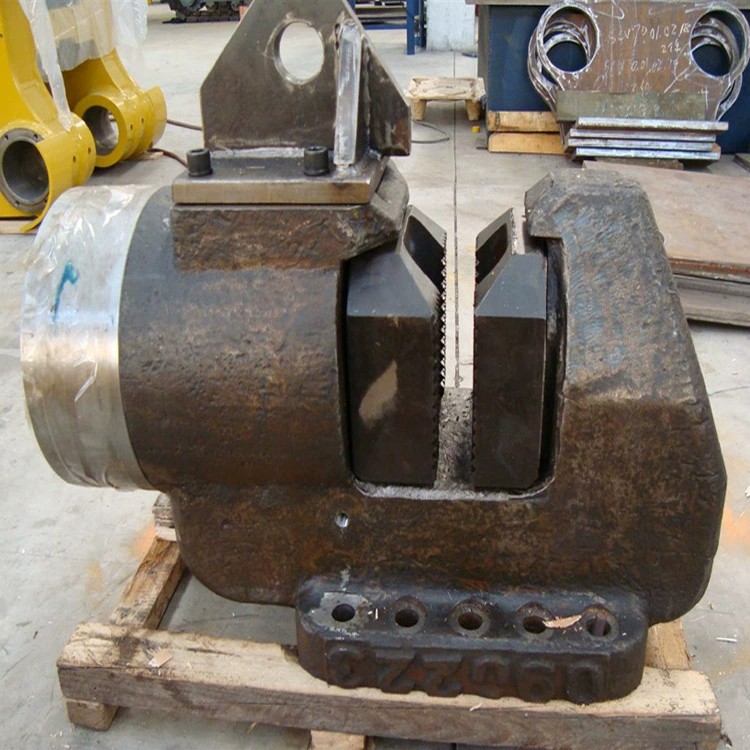

Vibratory Hammer Fixture-Hydraulic Vibratory Hammer Pile Fixture

updatetime:2022-08-29 13:46:19 pageviews:349views

A fixture refers to a device used in the mechanical manufacturing process to fix a processing object so that it can be constructed or tested in the correct position. The same goes for the pile hammer jig. Using the clamp with the pile driver can make performance more reliable and construction more efficient.

1. Introduction of piling hammer fixture

In the process of mechanical manufacturing, it is a device used to fix the object to be processed and make it occupy the correct position for construction or inspection, also known as a fixture In a broad sense, in any process, it is used to quickly, easily and safely The device that mounts the workpiece can be called a fixture. For example, welding fixtures, inspection fixtures, assembly fixtures, machine tool fixtures, etc., pile hammer fixtures. Among them, machine tool fixtures are common and are often referred to as fixtures. When machining the workpiece on the machine tool, in order to make the workpiece surface meet the technical requirements of the size, geometry and mutual positional accuracy with other surfaces specified in the drawing, it must be installed (positioned) and clamped (clamped) before machining. Pile hammer fixtures are usually composed of positioning elements (for determining the correct position of the workpiece in the fixture), clamping devices, tool setting guide elements (for determining the relative position between the tool and the workpiece or guiding the direction of the tool), indexing Device (enables the workpiece to complete the processing of multiple stations in one device, including rotary indexing device and linear moving indexing device), connecting elements and clamping parts (fixture base), etc.

2. Classification of piling hammer fixtures

The types of piling hammer fixing devices can be divided into: ① Universal fixture. For example, machine vices, chucks, suction cups, indexing heads and rotary tables have great versatility and can better adapt to the conversion of processing programs and processing objects. Their structures have been finalized, their dimensions and specifications have been serialized, and most of them have become standard accessories for machine tools. ② This is a special jig. Pile hammer clamps are specially designed and manufactured to meet the clamping needs of specific product parts in a specific process. The service object is specific and has a clear goal. Usually designed by the product manufacturer. Commonly used are lathe fixtures, milling machine fixtures, drilling fixtures (machine fixtures used to guide the tool to drill or ream holes on the workpiece), boring machine fixtures (machine fixtures used to guide the boring bar to drill holes on the workpiece) and mobile Fixtures (mobile fixtures for combined machine tool automatic lines). ③ Adjustable clamps. Hydraulic hammer clamps are special clamps that allow replacement or adjustment of parts. ④ Combined fixture. The fixture consists of standardized parts of different shapes, sizes and uses, and is suitable for trial production of new products and single-piece, small batch production and temporary tasks where products are frequently replaced. In addition to vices, chucks, indexing heads, and rotary tables, there is a more common name called tool handles. Generally speaking, when the term "tool holder" is used together, most of that holder refers to a tool handle.

The pile hammer clamp is used together with the pile driver to fix various pile types, which is very convenient and reliable.