VR Vibration Breaking Pick Specifications-Excavator Vibration Breaking Pick Manufacturer

updatetime:2022-08-29 13:40:46 pageviews:359views

The vibratory breaker is designed for the vibratory breaker pickaxe excavator, but is also suitable for mounting on wheel loaders and fixed working arms. Due to their robust design, they are ideal for demolition work, and this range of breakers is suitable for almost all municipal engineering crushing work. Large models are suitable for rock breaking. Vibratory crushing picks have proven to be useful for both penetration and impact crushing.

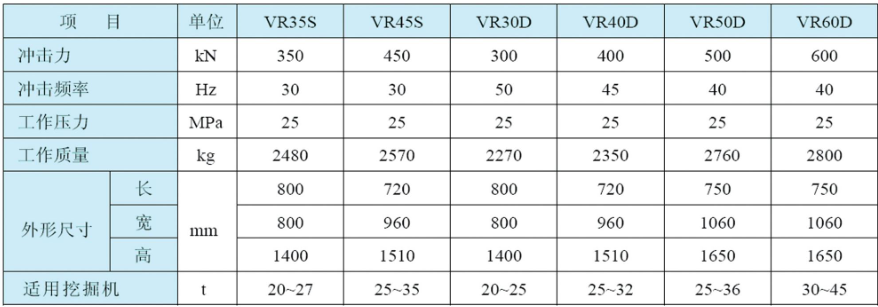

The models of vibratory breakers include vr35s, impact force 350kn, impact frequency 30Hz, working pressure 25MPa, working mass 2480kg, dimensions 800*800*1400, suitable for 20~27t excavators; Vr45s impact force 450kn, impact frequency 30Hz, working Pressure 25MPa, working mass 2570kg, dimension 720*960*1510mm, suitable for 25~35t excavator; Vr30d impact force 300KN, impact frequency 50Hz, working pressure 25MPa, working mass 2270kg, dimension 800*800*1400mm, suitable for 20~25t excavator; vr40d impact force 400kN, impact frequency 45Hz, working pressure 25MPa, working mass 2350kg, dimension 720*960*1510mm, suitable for 25~32t excavator; Vr50d impact force 500kN, impact frequency 40Hz, working pressure 25MPa, working mass 2760kg, dimension 750*1060*1650mm, suitable for 25~36t excavator; Vr60d impact force 600kN, impact frequency 40Hz, working pressure 25MPa, working mass 2800kg, dimension 750*1060*1650, suitable for 30 ~45t excavator.

Six models of vibratory breakers feature standard noise suppression. Low-noise design: In urban areas with noise restrictions, noise can be effectively reduced by shock-absorbing rubber pads and sealing boxes. Optional low noise bracket crusher. Crushing technology and heat treatment technology: Improve heat resistance and wear resistance. Low fuel consumption design: Under the condition of ensuring constant oil pressure, the cylinder volume and fuel consumption are reduced. Durability design of vibration crushing pick movement: The piston ring oil circuit design is adopted to reduce resistance and make the piston cylinder more durable. The vibratory breaker is designed to minimize the rebound force, protect the movement, and have a long service life. Bridge deck durability design: The bridge deck is made of high-strength steel plates to reduce wear and tear. Oil seal durability design: increase the oil return channel on the pressure surface of the oil seal to reduce the oil seal pressure and improve the service life of the oil seal.

Lightweight design: It can be matched with excavators and loaders. Low noise design: In urban areas with noise restrictions, the noise can be effectively reduced by shock-absorbing rubber pads and sealing boxes. Vibration crushing pick can choose low-noise bracket crusher. Long service life and lower use cost Alloy steel is selected, which has long service life, high-precision machining and heat treatment technology, and has good service durability. The vibrating breaker is easy and comfortable to operate and easy to maintain. Fine and reasonable oil pipe design and production, small clogging resistance, convenient and comfortable operation, simplified structure design and improved reliability. Simple structure, complete maintenance and repair immediately.